After two cups of strong coffee this morning I tackled an organizing project that was hangin' over my head. You see, I get a little corner of the garage for my storage and workspace for my fiber arts. This messy little corner needed an overhaul. I put finished yarn in one bin, raw fleece in another bin, etc. Sadly I had a whole category of "unfinished projects". To think I use to be a one-project-at-a-time girl and now I have a serious case of start-itis. Sigh. Well, I'm going to whittle away at the unfinished projects now. First I have to decide: fix, finish, frog, or forget. "Forget" is to literally throw in the the trash. Sometimes that's the best place for an unfinished project. Today I'm going to start with the easy ones:

A Sea-Silk tank that has already been blocked---all it needs is two side seems and to weave in the ends.

FINISH

A pair of thrummed mittens. The ends need to be woven in and all the little thrums need to be fluffed on the inside.

FINISH

Oh, what was I thinking? The design on this shawl doesn't stand out enough because of the lumpy hand spun yarn. Why waste the yarn?

FROG

Time to get to work.

Thursday, December 26, 2013

Monday, November 4, 2013

One Mushroom, Many Colors!

Yesterday I attended a class offered by the Puget Sound Mycological Society to learn more about mushroom identification. The whole class was fascinating and now have a better understanding of the processes one must go through to identify a mushroom. The participants brought in various mushrooms to ID. I spotted a grand Phaeolus schweinitzii - a "Dyer's Polypore"! I asked the student who brought it in if I could take it home at the end of class and she agreed. (Thank you!)

Upon returning home I promptly got out my large dyeing pot, chopped the mushroom, covered it with water and set it to simmer for about a half hour. I wish I would have weighed it. I'm guessing it was about 5 lbs. I added some ammonia and used a tin mordant and got the very orange skein dyed in about 1/2 an hour. I had so much dye material left I grabbed by little sample skeins and began adjusting the pH and the mordants. The skeins that turned out yellow had either no mordant (other than the residual tin floating around) or a pre-mordant with alum. Then I threw in some iron and my samples started coming out green! Some skeins I dipped in for 2 minutes to get a lighter color and some I left in for 1/2 an hour. It's amazing how many colors you can get from one mushroom!

Upon returning home I promptly got out my large dyeing pot, chopped the mushroom, covered it with water and set it to simmer for about a half hour. I wish I would have weighed it. I'm guessing it was about 5 lbs. I added some ammonia and used a tin mordant and got the very orange skein dyed in about 1/2 an hour. I had so much dye material left I grabbed by little sample skeins and began adjusting the pH and the mordants. The skeins that turned out yellow had either no mordant (other than the residual tin floating around) or a pre-mordant with alum. Then I threw in some iron and my samples started coming out green! Some skeins I dipped in for 2 minutes to get a lighter color and some I left in for 1/2 an hour. It's amazing how many colors you can get from one mushroom!

Thursday, October 31, 2013

Oh the Horrors!

Striking fear in the heart of all spinners! A Man-Eating Sheep is roaming the neighborhood. Happy Halloween!

Sunday, October 20, 2013

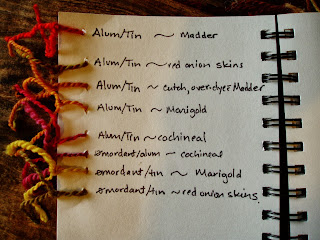

Mixed Mordant Experiment

Mordants are substances that dyers use to adhere dyes to fibers. Typically dyers use alum, copper, tin, tannic acid, or iron, among others. Each of the mordants will have a different effect on the color. A mordant can brighten, dull, or change a color all together. You can add the mordant to the fiber before, during, or after the dyeing process. My mixed mordant experiment goes like this: I would pre-mordant roving, then spin it into singles, then ply together singles that had different mordants. My prediction: if I dip a multi-mordant strand into the dye it should come out with two colors, giving it a barber-pole effect.

Mordants are substances that dyers use to adhere dyes to fibers. Typically dyers use alum, copper, tin, tannic acid, or iron, among others. Each of the mordants will have a different effect on the color. A mordant can brighten, dull, or change a color all together. You can add the mordant to the fiber before, during, or after the dyeing process. My mixed mordant experiment goes like this: I would pre-mordant roving, then spin it into singles, then ply together singles that had different mordants. My prediction: if I dip a multi-mordant strand into the dye it should come out with two colors, giving it a barber-pole effect. After I dissolved a teaspoon of tin in some water I let it cool completely. I added the wool and slowly heated the mordant bath until it was simmering. I let it simmer for half an hour and then let it all cool to room temperature. I carefully rinsed the roving. Essentially there was no sudden change in temperature or agitation of the wool to prevent felting.

Next I did the same procedure with an alum mordant. After all the roving was dry I spun singles then plied the different mordant strands together.

The results were mixed. Some of the color variations were too subtle to notices. Others had the barber-pole effect that I was looking for. The yarn that I'm holding above was made with a tin/alum combination yarn dyed with red onion skins.

This pink yarn was make with one strand of alum and one strand with no mordant plied together than dyed with cochineal.

In general I don't enjoy keeping records, but I did take notes this time. One thing that I learned during this experiment is that I really like what tin does to the natural dyes. The brightest colors came from the tin.

As soon as the little skeins were dry, I rolled them into balls and started a knitting project.

Friday, October 18, 2013

Mushroom Dye Class

The mushroom dye class put on by the Puget Sound Mycological Society was lots of fun. Our teacher was Alissa Allen and you can see her website here: Mycopigments.com We tore up a bunch of mushrooms and put them in a pot. Alissa told us about checking the ph to bring out the colors.

There was a display of mushroom and lichen dyed fibers and garments.

We each dyed 2 silk scarfs. This all took us only 2 hours and I was happy to leave prepared to go out on my own and try dyeing with mushrooms. I very much appreciated the handout Alissa gave us that will help my identify the most common mushrooms for dyeing. I'm going to try to get out this weekend for a hike and see if I can find some.

There was a display of mushroom and lichen dyed fibers and garments.

We each dyed 2 silk scarfs. This all took us only 2 hours and I was happy to leave prepared to go out on my own and try dyeing with mushrooms. I very much appreciated the handout Alissa gave us that will help my identify the most common mushrooms for dyeing. I'm going to try to get out this weekend for a hike and see if I can find some.

Monday, October 14, 2013

A Blank Canvas.

This weekend I spun up any wool in my stash that is white. This is all in preparation for dyeing, of course. Tonight I'll be attending a Mushroom Dyeing class. Earlier this fall I joined the Puget Sound Mycological Society with a plan to learn about mushrooms for eating and dyeing. I've been reading and watching youtube videos about mushroom identification. This weekend I attended the annual event that the Puget Sound Mycological Society puts on. There were TOO MANY people there when I went on Saturday so I had a hard time seeing all the displays. How wonderful that the problem was too much interest!

Now that I have some white yarn---my blank canvas---bring on the mushrooms!

Now that I have some white yarn---my blank canvas---bring on the mushrooms!

Tuesday, October 8, 2013

On and on and on...

Lace knitting has always been one of my favorite things to do. This one has been quite a challenge because it's boring in the middle. The middle part of this shawl has a 6 row repeat that needs to be done 30 time. It takes over an hour to do the 6 rows. I'm 15 repeats in to. Ugh. I think it will all be worth it because the pattern is lovely. It's a free knitty pattern called Anthemion. I started it LAST MAY and I'm half way done. This is hands down the longest knitting project I have ever done.

Saturday, October 5, 2013

Madder-Dyed Scarf

Thursday, October 3, 2013

Dyeing with Madder

From left to right:

1. handspun wool that was once dyed with cutch then over-dyed with madder with an alum mordant

2. hand carded, hand spun blended alpaca that I spun last month, dyed madder/alum

3. Norwegian White hand spun dyed with madder/alum

4. Norwegian White hand spun dyed with madder/iron

I've been dyeing.

These are the yarns that I'm using for a little weaving project. I'm warping the loom now.

Wednesday, September 25, 2013

Sometimes you just have to stop.

I really don't like hand carding. Forgetting this fact, I started a little blending project. Using several kinds of natural colored alpaca I hand carded about 40 little tuffs to spin from. After carding about 3 I remembered: I really don't like hand carding. Ah, but my drum carded definitely will not work with alpaca. So I carried on...

After making one skein of two ply yarn, I terminated the project. Spinning, for me, is suppose to be enjoyable. Now I'm going to get out the drum carder and some WOOL and have some fun.

After making one skein of two ply yarn, I terminated the project. Spinning, for me, is suppose to be enjoyable. Now I'm going to get out the drum carder and some WOOL and have some fun.

Sunday, September 22, 2013

Norwegian White

Have you ever heard of the breed Norwegian White? I hadn't until I saw some top at Weaving Works: Norwegian White Top for $1.70/oz. I bought about 8 oz and begun to spin it up into a lace weight yarn. It's so soft! The breed Norwegian White was not in any of my reference books so I googled it. There's not much information out there. It became an official breed in 2001.

I'm loving the Norwegian White and getting ready for my next dyeing project by spinning up some white skeins. I wonder how it will take dye? Stay tuned, we'll find out.

I'm loving the Norwegian White and getting ready for my next dyeing project by spinning up some white skeins. I wonder how it will take dye? Stay tuned, we'll find out.

Wednesday, June 12, 2013

Sunday, April 28, 2013

A Green Spring

Seattle got to experience a few days of glorious weather. The sun inspires me to dye because I know it will help me dry in a fraction of the time it would take indoors. This time I decided to try a dye brand that's new to me even though it's been around since 1879. I bought Cushing's Olive Green, Green, and Bright Green. I started with the Bright Green and dyed 8 oz Norwegian White roving. I had never heard of Norwegian White before but a google search got me up to speed on this type of wool. After spending just an half hour on the stove, I left the roving in the dye pot over night. In the morning the water was clear. I drained it off and rinsed the roving and laid it outside to dry. It was almost 70 degrees out and by evening the roving was dry.

Now the rain it back and I can sit inside and spin up my spring time yarn.

Now the rain it back and I can sit inside and spin up my spring time yarn.

Sunday, February 17, 2013

Second Sock Yarn and Emergency Knitting Project

My second attempt of a sock yarn turned out much like my first. However, I chose a different pattern with an all around better fit. I used a pattern from the book Knitting on the Road by Nancy Bush. I have spun up my 3rd sock yarn and it's drying as I write this. I'm excited to make my next pair.

Meanwhile, I finally finished a knitting project that I started last summer. It's a pattern from the Wild Fibers Magazine Fall 2007 called Bonnie by Lisa Lloyd. I do believe that I'm the only person in the universe to knit this patter---it's not on Ravelry! My Ravelry account is broken and I haven't been able to upload anything for months. Once I figure out how to fix it I'll get this sweater up and I suppose I'll be the first to do that. It's a pretty boring pattern so I can see why no one else has knitted it. It took a long time because it lived in my car as an emergency knitting project. I didn't have any emergency knitting situations so finally I just brought it out and finished it.

Monday, January 28, 2013

My Second Sock Yarn

It looks a lot like my first sock yarn. This one is from Blue Face Leicester top. I spun 7 oz into a 3-ply yarn. I've set the twist and it's drying now. I can't wait to start another pair of socks!

Sunday, January 13, 2013

Shield Lace Hat

A while back I tried to spin 100% alpaca and didn't enjoy it at all. The lack of crimp made it seem slippery in my hands and I couldn't get a consistent yarn so I gave up. Recently I was heading out to my once-a-month spinning group at the Ballard Library and I needed something to spin so I grabbed a bag of brown alpaca from my stash. I'm not sure where I acquired this roving. This time around I really liked spinning it and I chose to make a lace weight 2-ply yarn.

I ended up with a nice fat skein and then set about to find a pattern to knit. I came across Shield Lace Hat by Kristin Lamm. Perfect! After watching a few youtube videos, I used the tubular cast-on method. It's brilliant! I love how the edge looks with this kind of cast-on.

You can't really see the shield lace pattern in this hat, but I like it none the less.

I ended up with a nice fat skein and then set about to find a pattern to knit. I came across Shield Lace Hat by Kristin Lamm. Perfect! After watching a few youtube videos, I used the tubular cast-on method. It's brilliant! I love how the edge looks with this kind of cast-on.

You can't really see the shield lace pattern in this hat, but I like it none the less.

Friday, January 11, 2013

Shades of White

Lichen blanched in the windowsill.

Cookies powdered with sugar.

Wool scoured.

Continuing with my love of natural colored fiber,

I am spinning white.

Tuesday, January 1, 2013

Happy New Year!

Lately I've been on a natural colored fiber kick. I have also been interested in trying to blend natural fibers together. I ended up with little "samples" that I knitted all together to make a beanie The brim is made with wool and rabbit, the brown is wool plied with alpaca, and the dark gray is a variety of wool. I tried to give the hat away, but so far no takers. It's pretty warm, so maybe I'll wear it.

Subscribe to:

Comments (Atom)

.JPG)

.JPG)

.JPG)

.JPG)